Home – Info Center – Blogs – What Tests To Identify Quality Outdoor Solar Lights?

As an outdoor product, the quality requirements of solar lights will be very high, so it is very important to carry out various tests, because these tests can comprehensively assess the quality, performance and safety of outdoor solar lights, ensure that the solar yard lights can meet the relevant standards and requirements, and improve their reliability and safety.

By testing various components such as solar panels, batteries, LED, etc., we can find potential problems in time before the mass production, thus improving the quality and performance stability of the product, which is also the quality line that we have been adhering to at FLIGREEN.

Table of Contents

IP Test

Solar lights are typically used in outdoor environments that are often exposed to variable weather conditions and dust pollution. Therefore, it is crucial to test solar lights for water and dust resistance.

The purpose of waterproof testing is to ensure that the luminaire works properly even in rainy or humid environments, and to avoid damage to electrical components, short circuits or other failures. Such tests usually include a water shower test to simulate a rainy environment and a water immersion test to simulate a flooded situation. Through these tests, the performance of the luminaire can be assessed under different humidity and moisture conditions.

Dust tests, on the other hand, are designed to ensure that the solar outdoor lights will perform well in dusty environments. Dust can cover the surface of lights, affecting its luminous efficacy, or even get inside the lighting and cause damage to the electrical components. Dustproof testing usually includes tests that simulate dusty environments to evaluate the performance of the solar outdoor lighting in terms of dustproofing.

When conducting waterproof and dustproof tests, professional testing equipment and methods are usually applied to simulate the various conditions that may be encountered in the actual environment. Through these tests, we can ensure that the solar lamps can work properly under all kinds of harsh conditions and improve the quality and reliability of our products. If you want to get more detailed IP test information, can read: What Is IP Rating?

https://www.youtube.com/watch?v=aP0aXuqyiwE

Salt Spray Test

Metal enclosures can be at risk of corrosion in a wide range of environments, and are particularly vulnerable to corrosion in harsh environments such as humidity and salt spray. Salt spray testing accelerates the assessment of the corrosion resistance of metal enclosures by simulating these harsh environments.

In salt spray testing, the metal enclosure is placed in an environment containing salt spray, and after a certain period of exposure, its surface is observed for corrosion, rust and other phenomena. This test method can simulate in a short time the corrosion process experienced by the metal enclosure in actual use, thus quickly assessing its corrosion resistance.

https://www.youtube.com/watch?v=fCgLGbRJBD4

Battery Overcharge And Discharge Test

Lithium battery is the core component of solar lights, so overcharge and discharge test is an important part of lithium battery quality control. Through the battery overcharge and discharge test, we can filter out the poor performance of the battery, to ensure that only meet the requirements of the battery can be used in the production of solar lighting.

At the same time, lithium batteries in the overcharge and overdischarge state may produce safety hazards. Overcharge, the battery may produce a large amount of internal gas, resulting in battery expansion, and in severe cases may even cause an explosion. And over-discharge may lead to short circuit inside the battery, causing damage to the battery or even causing a fire.

Therefore, overcharging and overdischarging tests on lithium batteries can also assess the safety performance of the battery under these extreme conditions to ensure the safety of the battery in actual use.

https://www.youtube.com/watch?v=v6PBiRPD-ME

Battery Capacity Test

Battery capacity testing confirms the actual charge capacity of a lithium battery, i.e. the amount of electrical energy a lithium battery can store. Through the test, it is possible to know whether the actual storage capacity of the battery matches the manufacturer’s nominal capacity and whether it meets the expected performance index.

The capacity of Li-ion batteries will gradually decrease as the usage time grows, which is due to the aging of the battery materials and the loss during cyclic charging and discharging. Through testing, the battery’s decay can be detected early, and maintenance or replacement decisions can be made in advance to ensure the normal operation of the solar light.

https://www.youtube.com/watch?v=um6rBa4RCKw

High And Low Temperature Testing Of Batteries

High and low temperature testing ensures the safety of batteries under extreme temperature conditions. Under high temperature conditions, batteries may face safety risks such as thermal runaway, overheating or even fire. Through high temperature testing, we can assess that the thermal stability and safety of the battery, so that we can take appropriate measures to prevent battery accidents. Under low-temperature conditions, batteries may face problems such as charging difficulties and performance degradation, etc. Through low-temperature testing, we can assess the battery cold-resistant performance, thus ensuring the normal use of batteries in low-temperature environments.

https://www.youtube.com/watch?v=P8XN7wtRqU0

LED Aging Test

As the core component of solar lights, LED plays a very important role, LED aging test can simulate the actual use of the environment, including temperature, humidity, voltage and other conditions, in order to test the LED performance in these environments, to assess the stability of photoelectricity performance of LED solar lights after long-term use, in order to ensure that it continues to provide a stable lighting effect.

Through the aging test, we can find the possible problems and defects of LED in long-term use , providing feedback for the product design and production process, helping to optimise the outdoor solar light structure, materials and processes, and improving product quality and stability. During the aging process, if there are quality problems, they will usually be exposed at this stage, thus avoiding the delivery of unqualified products to customers.

https://www.youtube.com/watch?v=MzsZkEORtDY

Lumen Output Test

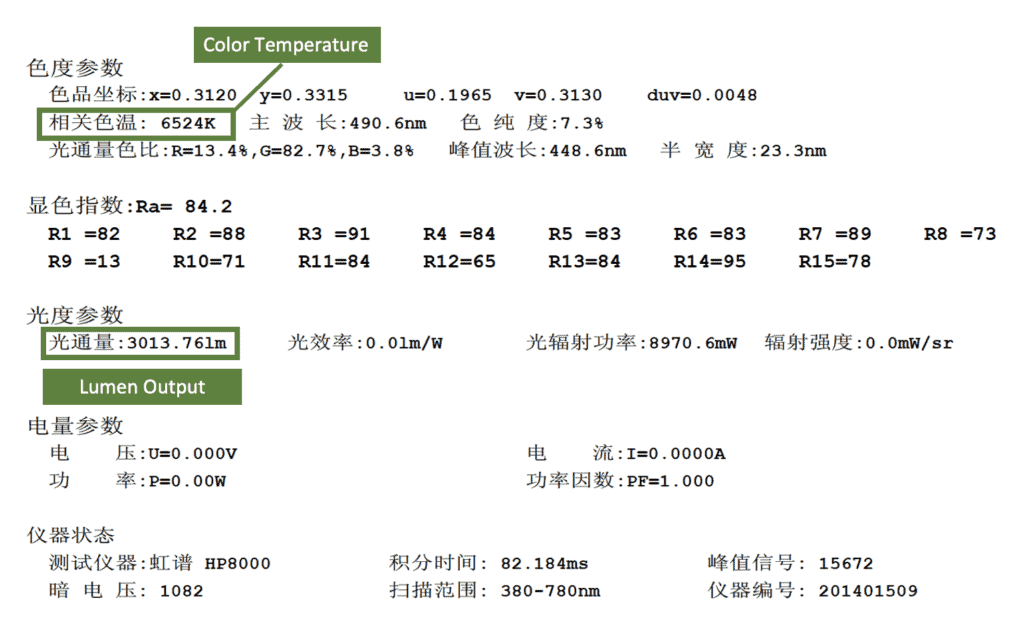

A lumen is a unit of measurement for the luminous intensity of a light source, and lumen testing of solar lights can be used to assess their lighting effectiveness. The test determines the actual brightness of a solar light to ensure that it provides adequate illumination, and the lumen test determines whether the actual lumens are consistent with the manufacturer’s nominal lumens.

Lumen testing helps consumers compare the lighting performance of different solar light products. By comparing the lumen values of different products, consumers can quickly choose the right solar light for their needs.

Colour Temperature Test

Different colour temperatures produce different light effect, for example, low colour temperatures (about 3000K) produce warm white light, which gives people a cozy and comfortable feeling, and is suitable for resting places; whereas high colour temperatures (e.g. 5000K or above) produce white or blue light, which may cause people to feel harsh and uncomfortable, and it may suitable for commercial lighting.

The colour temperature test helps consumers to compare the quality of different solar light products. By comparing the colour temperature values of different products, users can choose the light colour temperature that meets their preference.

For both the lumen test and the colour temperature test, you can use the integrating sphere to test them out, and the following is a sample test report:

Drop Test

Drop test can simulate the free fall that the product may be subjected to during transportation, loading and unloading. By testing the drop impact of the outer box, we can evaluate the impact strength and protection ability of the outer box, and at the same time, we can find out the possible defects and problems of the product outer box in the process of designing and manufacturing, so that we can take measures to improve it in time. This helps to improve product quality and reliability, and reduce possible damage and complaints about products during transport.

https://www.youtube.com/watch?v=xP-KBYPf8cM

Solar Panel Electroluminescence(EL) Test

With the rapid development of the solar power industry, PV panel EL tester plays an increasingly important role in the solar power system.EL test is a method of quality inspection using the photoluminescence principle inside the solar panel. By performing EL test on solar panels,we can detect problems that may lead to performance degradation in time,such as cell rupture,cracking,black chip,serious gate breakage,solder breakage,weld breakage,etc.Thus,we can ensure the quality of the solar modules and improve the stability and high efficiency of the cells.

https://www.youtube.com/watch?v=hlhqKTQ8acA

Solar Panel Current and Voltage Testing

Current and voltage testing is a key means of evaluating the performance of solar panels. By measuring the current and voltage output of a solar panel under different light conditions,we can understand key performance parameters such as conversion efficiency, maximum power point (MPP), and output stability of the solar panel. If the current or voltage output of a solar panel exceeds its design range, it may cause damage to the connected equipment or system. Through testing, it is possible to identify and address potential safety risks in a timely manner.

https://www.youtube.com/watch?v=HZf-sm3UXX0

Conclusion

As an environmentally friendly and energy-saving lighting, the quality of solar lights is directly related to the user’s lighting experience. In order to ensure that solar lights can work stably and efficiently in practical applications, they must undergo a series of quality tests.

The importance of these tests is that they provide a comprehensive assessment of the performance, safety and reliability of the solar lamps, helping manufacturers to identify potential problems and make improvements to ensure that the final product meets user requirements and industry standards.

Related Blogs

Share Via:

Get in Touch with Us Now!

Got questions or feedback? We’d love to hear from you! Just fill out the form below, and our friendly team will respond ASAP.