What's IP Rating?

Most Comprehensive Explanation In Lights Industry

Home – Info Center – Blogs – What’s IP Rating?

By Michael Zhang || Updated on 13rd March 2024

Michael Zhang is a seasoned professional with 15 years of experience in the solar lights industry. Throughout his career, he has been actively involved in product design and developing, gaining valuable expertise and insight into the industry. Known for his dedication and professionalism, Michael has contributed significantly to the growth and success of various solar lights projects. His extensive knowledge and hands-on experience make him a trusted authority in the field, and he continues to innovate and excel in his role.

Manufacturers often use the terms “dustproof” or “waterproof” to describe the robustness of their products. However, such descriptions do not go any further than explaining the degree of protection. Therefore, to clarify and reinforce toughness, they use IP ratings to define the level of resistance of their products.

The IP rating explains the level of resistance of any product to harsh environmental/weather conditions. With the help of IP rating, buyers/customers can determine the water and dust resistance of any product. If any manufacturer claims that a product is waterproof or dustproof but it does not specify what strength of water dust it can withstand but by mentioning the IP rating, you can get accurate information about waterproofing.

Table of Contents

Basic Knowledge Of IP Rating

What IP Rating Means?

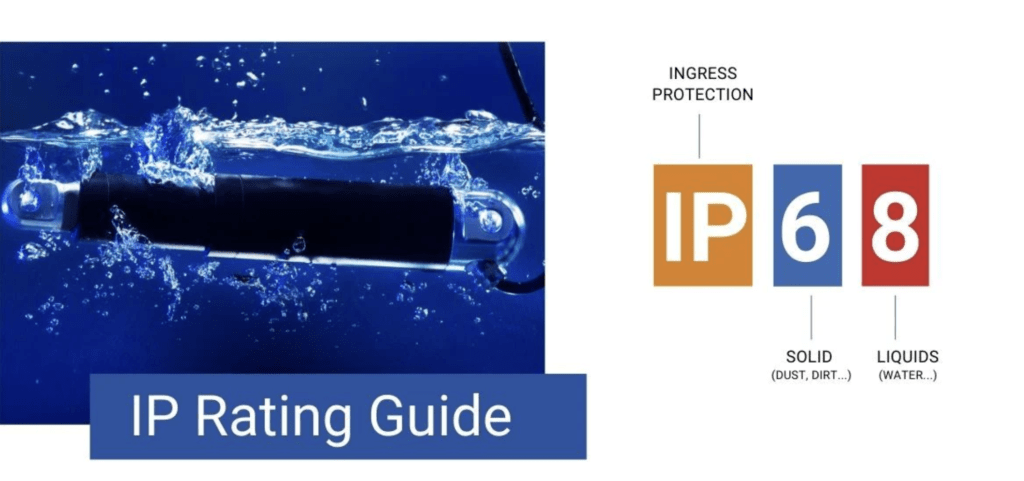

The IEC has developed an Ingress Protection (IP) rating, which classifies the ability of an enclosure to resist the ingress of dust or liquids. It usually consists of two digits. The first number indicates protection against solids and the second number indicates protection against liquids. Therefore, the higher the number following the IP, the better protection it provides.

Therefore, for simplicity, IP ratings indicate the ability of a device to resist foreign objects such as dust, water or unwanted contact. These ratings are used in a wide range of products throughout the industry, such as: lamps, telephones, irons, televisions, etc.

What IPX Rating Means?

The letter “X” in the IP rating indicates that the device is not rated for any particular level of protection. So, for example, if X replaces the first digit of the IP rating, the machine has no available data on protection against solid ingress/dust. If it replaces the second digit, the machine has no liquid ingress protection rating.

Thus, IPX6 means that an object is resistant to spraying water, but has not been subjected to any tests to clarify the solid contact rating. Whereas IP6X indicates exactly the opposite fact, that solid entry is safe, but there is no information about water resistance.

What Do The Numbers Mean In An IP Rating?

The IP rating consists of two digits: the first digit indicates the level of protection against solid objects and the second digit indicates the level of protection against liquids.

First Digit Means

The first digit of the IP rating specifies the level of protection against solids such as dust, fingers or any tools, etc. The protection classes for solids are X,0,1,2,3,4,5,6 Each number indicates a different protection attribute.

| 1st Digit | Protection Against | Description |

|---|---|---|

| X | – | No data is available for specifying protection grade |

| 0 | – | No protection against contact or ingress of solid |

| 1 | > 50 mm/2.0 in | It is protected against larger body surfaces, but no protection if you intentionally touch it with a body part. |

| 2 | > 12.5 mm/0.49 in | Protection against fingers or similar objects |

| 3 | > 2.5 mm/0.098 in | Tools, thick wires, etc. |

| 4 | > 1 mm/0.039 in | Most wires, slender screws, giant ants, etc. |

| 5 | Dust protected | Partial protection from dust; the dust can still enter |

| 6 | Dust-tight | Dust-tight. (No dust can enter. A fixture must withstand an eight-hour vacuum test.) |

Second Digit Means

The second digit of the IP rating describes the degree to which the enclosure protects the internal components from various types of moisture (spray, dripping, submersion, etc.). It is categorised as X, 0, 1, 2, 3, 4, 5, 6, 6K, 7, 8, 9 and 9K. Similarly to the first digit, they define different degrees of protection.

| 2nd Digit | Protection Against | Description |

|---|---|---|

| X | – | – |

| 0 | None | – |

| 1 | Dripping water | Vertical water drop will not affect when mounted at an upright position on the turntable and rotated at 1 RPM |

| 2 | Dripping water when tilted at 15° | Vertical dripping water will not affect when the fixture/object is tilted at 15 degrees from the normal position |

| 3 | Spraying water | Water spray (with a spray nozzle or oscillation tube) up to 60 degrees from the vertical direction will not affect the fixture. |

| 4 | Splashing of water | Water splashing (with a no-shield spray nozzle or an oscillating fixture) from any direction will not cause any harm. |

| 5 | Water jets | Water projection (with a 6.3mm nozzle) from any direction will not cause any harm. |

| 6 | Powerful water jets | Strong jets of water (12.5 mm) directed from any angle shall not cause damage |

| 6K | Powerful water jet with high pressure | Strong water jets (6.3 mm nozzle) directed at the enclosure from any angle at high pressure shall not cause any damage. |

| 7 | Immersion up to 1m | Harmful water ingress is not permitted when the enclosure is immersed in water (up to 1 meter of submersion) under defined pressure and time conditions. |

| 8 | Immersion on 1m or more | The object is capable of continuous submerging under manufacture-specified conditions. |

| 9 | High temperature and High water pressure | Can resist high temperatures, high water pressure, and stream |

| 9K | Powerful high-temperature water jets | Safe from close-range, high temperature, and high-pressure spray-downs. |

How Many Types Of IP Ratings Are There?

The table below shows all the levels of water and dust resistance currently available:

| 1st Digit | Solid Ingress Protection | 2nd digit | Liquid Ingress Protection |

|---|---|---|---|

| 0 | No protection | 0 | No protection |

| 1 | Protection from solids bigger than 50mm in diameter | 1 | Protection against vertical water dripping |

| 2 | Protection from the object over 12mm; fingers or similar object | 2 | Protection against vertically dripping water up to 15 degrees from its normal position |

| 3 | Protection from objects larger than 2.5mm in diameter | 3 | Water spray protection up to 60 degrees from a vertical position |

| 4 | Protection against solid objects over 1mm | 4 | Protects from splash weather irrespective of any direction |

| 5 | Partial protection against dust | 5 | Partial water jet protection at low-pressure |

| 6 | Total dust protection | 6 | Protection against strong water jets. |

| - | - | 6K | High-pressure water jet protection |

| - | - | 7 | Protected in 1m water immersion; test duration is 30 min. |

| - | - | 8 | Protected for long time water immersion |

| - | - | 9 | Protection from high temperature, high water pressure, and stream |

| - | - | 9K | Powerful high-temperature water jets |

How To Make Things Waterproof?

Ensuring that a product reaches the appropriate IP rating can be a challenging task, as it involves multiple considerations and tests. Below is a short list of things to consider in order to achieve a better seal:

1.Rubber Ring

Start with a rubber waterproof ring – the easiest shape of opening to seal is round, because you can use standard O-rings and robust radial seals that provide uniform sealing force around the circle.

2.Proper Gasket Compression Caps

Proper gasket compression caps are important – individual gaskets need to be well supported on all sides. Gasket “blow-out” from the squeeze area is a common cause of seal failure.

3.Tolerances

Tolerances are important – the harder the part, the easier it is to seal. For example, the deformation of a plastic housing under gasket loading cannot be ignored. Similarly, the gasket compression percentage needs to be kept within reasonable limits.

4. Remark

Interestingly, sealing something completely is usually a bad idea. There needs to be a way for air to move in and out of the enclosure, usually through hydrophobic membrane vents. These prevent the unit from exploding due to changes in air pressure, and provide a way for water vapour that enters (and will enter) the enclosure to escape (rather than condense on the components).

Ingress Protection (IP) Testing Detailed Explained

Waterproof and dustproof testing typically employs a series of standardised test methods to assess a product’s waterproof and dustproof performance under different environmental conditions. The following are common test methods:

Waterproof Test

Why are products tested for water resistance? The main purpose of waterproof testing a product is to ensure that it will function properly in a given underwater environment and will not be damaged or pose a safety risk due to water ingress.

| 2nd Digit | Test Content | Test Method | Placement Location | Duration |

|---|---|---|---|---|

| 1 | Drip Test | Water drops from a specific direction onto the product surface | Tilted platform | 10 minutes |

| 2 | Tilted Drip Test | Similar to IPX1, but with higher flow rate and frequency of water drops. | Tilted platform | 10 minutes |

| 3 | Spray Test | A fixed nozzle is used to spray water onto the product at a specific flow rate and pressure. | The spray angle is usually 60 to 70 degrees, from two opposite sides of the product. | 5 minutes |

| 4 | Splash Test | Similar to IPX3, but with higher water pressure to simulate stronger water splashes. | The spray angle is usually 360 degrees, from all directions. | 5 minutes |

| 5 | Water Jet Protection | High-pressure water jets are directed onto the product surface. | The spray angle is usually 180 degrees, from all directions. | 3 minutes |

| 6 | Powerful Water Jet Protection | Similar to IPX5, but with even higher water pressure. | The spray angle is usually 180 degrees, from all directions. | 3 minutes. |

| 6K | Powerful Water Jet Protection | Similar to IPX6, but with even higher water pressure. | The spray angle is usually 180 degrees, from all directions. | 3 minutes. |

| 7 | Temporary Immersion Protection | The product is fully immersed in water | Depth is 1 meter. | 30 minutes |

| 8 | Continuous Immersion Protection | The product is fully immersed in water | Depth is exceeding 1 meter. | 30 minutes or longer |

| 9 | High-pressure Water Jet Protection | High-pressure water jets are directed onto the product to simulate the effect of high-pressure cleaning equipment. | From all directions. | 30 seconds |

| 9K | High-pressure Steam Jet Protection | High-pressure steam are directed onto the product to simulate the effect of high-pressure cleaning equipment. The water temperature during the test is maintained at 80°C. | From all directions. | 3 minutes |

Dustproof Test

Why are products tested for dust resistance? The main purpose of dust testing is to ensure that a product will function properly in dusty environments, such as dust and solid particles, and will not be damaged or pose a safety risk due to dust ingress.

| 1st Digit | Test Content | Test Method | Duration |

|---|---|---|---|

| 1 | Protection against solid objects larger than 50mm | The product is placed under a simulator with solid objects larger than 50mm in diameter. | 1 minute |

| 2 | Protection against solid objects larger than 12.5mm | The product is placed under a simulator with solid objects larger than 12.5mm in diameter. | 3 minutes |

| 3 | Protection against solid objects larger than 2.5mm | The product is placed under a simulator with solid objects larger than 2.5mm in diameter | 10 minutes |

| 4 | Protection against solid objects larger than 1mm | The product is placed under a simulator with solid objects larger than 1mm in diameter. | 10 minutes |

| 5 | Dust protection | The product surface is covered with fine dust particles. | 8 hours |

| 6 | Complete dust protection | The product surface is covered with fine dust particles | 8 hours |

A Guide To IP Ratings and IP Zones

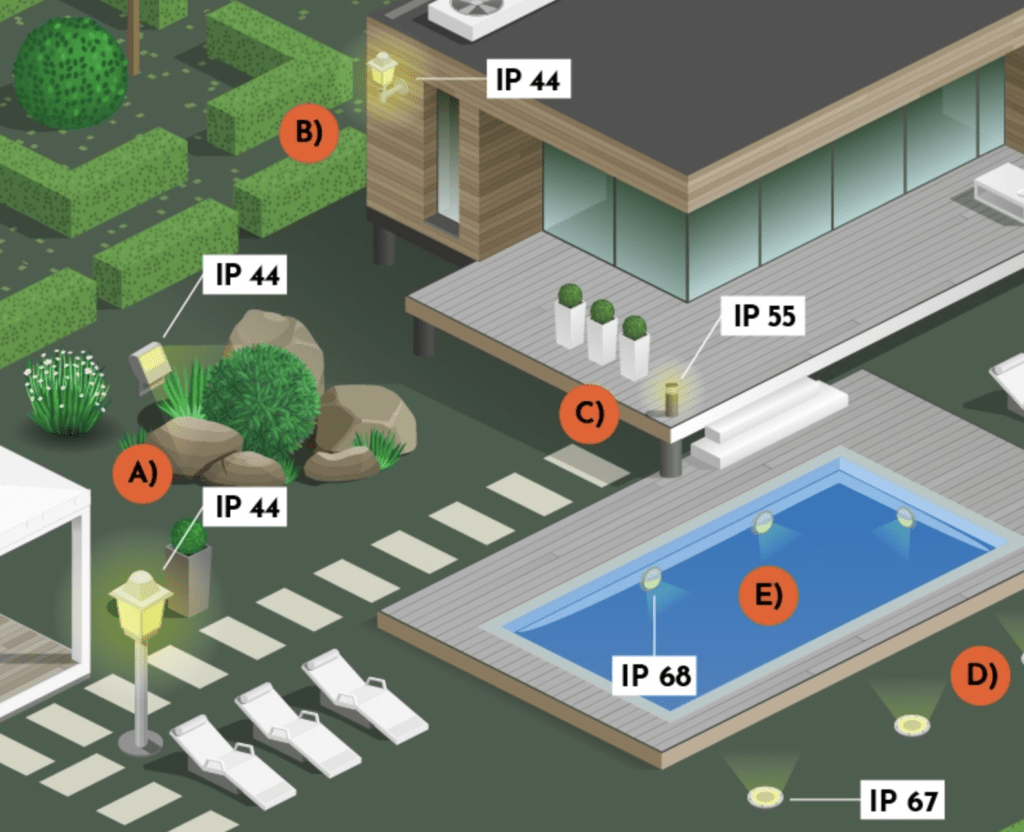

Due to the different degree of exposure of the luminaire to external objects and liquids in different installation scenarios, the corresponding products require different IP ratings. For example, indoor environments are relatively dry and usually only require lower protection levels, whereas outdoor environments may be exposed to more intrusion from external objects such as water and dust, and therefore require higher levels of protection.

IP Rating For Bathroom Lighting

Indoor lighting is not exposed to dusty or humid environments and therefore does not require a higher IP rating. A minimum rating of IP20 works well indoors. It protects fingers or similar objects. Bathroom lighting, however, requires a higher IP rating to protect against moisture.

Indoor bathroom and toilet lighting requires a higher waterproof rating to be considered as these areas are often exposed to water vapour and steam, with high levels of humidity and moisture present. It is generally recommended to choose lighting with an IP44 rating or higher. The following are recommendations for the waterproof rating required for bathroom and toilet lighting:

Bathroom Mirrors

This is the minimum recommended waterproof rating IP44 for general lighting equipment in bathrooms and toilets. These fittings are able to protect against water vapour and small amounts of splash water, for example, wall lights in front of bathroom mirrors or ceiling lights in bathrooms.

Shower Rooms Lightings

A higher waterproof rating for areas that are more vulnerable to water vapour and splashing water, for example, in shower rooms or around the bath. lighting fittings with an IP65 rating offer more reliable waterproof protection by preventing the ingress of higher water pressures and jets of water.

LED Bathtub Lights

For the inside of a bathtub or in the shower area, especially where water is jetted directly from the shower head, lighting fittings with an IP67 rating are recommended. These fittings can be fully immersed in water for a short period of time, providing a higher level of water resistance.

Spa Lighting

For use in more extreme environments, such as deep water immersion or spa areas, consider choosing IP68 rated lighting. These devices offer the highest level of water resistance and can be submerged in water for extended periods of time without damage.

IP Rating For Outdoor Lighting

Luminaires are often placed outdoors in extreme weather conditions: rain, storms and heavy dust. Therefore, only luminaires with a higher IP rating can withstand such conditions. For this reason, you can go for IP44-IP68 where the lighting is considered to be installed. But for outdoor use, IP68 is an ideal choice. It ensures complete protection against dust and water.

Depending on where you are going to place the luminaire, it should have a higher or lower protection rating. The areas that are going to be more exposed to splashes or any kind of direct contact with water should have a higher number than the rest.

Zone A: Lighting of entrances, paths, walkways or stairways. For this zone, luminaires with an IP44 rating are recommended, depending on their distance from the pool.

Zone B: Lighting of steps. As in the first zone, we will use IP44.

Zone C: Lighting near the pool. In this case, we will increase the safety rating to IP 55 to protect against splashing and pressurised water jets.

Zone D: Lighting in the pool area. This area will be regularly submerged in water so we will have to install IP67 luminaires.

Zone E: Lighting inside the pool. The solar luminaires will be permanently immersed in water, so it will have to have the maximum protection against dust and water with an IP68.

FAQs

IP68: The Top IP Waterproof Rating.

The IP67 waterproof rating means that the product can be submerged underwater for a short period of time, but is not suitable for swimming.The first number 6 of IP67 indicates protection against solid objects, and the second number 7 indicates protection against water, i.e. protection against short periods of submergence underwater, e.g. rain or accidental dropping into the water, but it is not recommended for prolonged periods of time in the water.

IP64 provides a degree of protection against rain, but is not specifically designed for use in heavy rainfall environments. the first number 6 of IP64 indicates protection against solid objects and the second number 4 indicates protection against water, i.e. capable of preventing the ingress of rain for short periods of time, but not suitable for prolonged exposure to heavy rain.

The IP67 waterproof rating means that the product can be submerged underwater for a short period of time, but is not suitable for swimming.The first number 6 of IP67 indicates protection against solid objects, and the second number 7 indicates protection against water, i.e. protection against short periods of submergence underwater, e.g. rain or accidental dropping into the water, but it is not recommended for prolonged periods of time in the water.

IP65 is suitable for general rainy day use but is not suitable for heavy rain environments. the first number 6 of IP65 indicates protection against solid objects and the second number 5 indicates protection against water, i.e. protection against the intrusion of sprayed water, but it is not suitable for prolonged exposure to heavy rain and prolonged immersion in water is not recommended.

Yes, IPX8 means that the product can be immersed in water for a long period of time without damage, so it is possible to place an IPX8 rated product for use in the shower.

Yes, IPX8 usually indicates that a product can be immersed in water for a long period of time without damage, so it is possible to use an IPX8 rated product while swimming.

Conclusion

An IP rating is essential for any electronic device to ensure protection against solids and liquids. The same necessity applies to solar lights, where the protection index is one of the most decisive factors when choosing one solar product over another, and there is a trade-off between the level of protection of a product in different environments and the costs and benefits. Increasing the level of protection usually requires the use of more expensive materials and manufacturing processes, which can increase the cost of the product. Therefore, a balance between cost and performance needs to be considered when selecting the level of protection.

In FLIGREEN you can find a wide range of solar lights that adapt to any style and need, from solar garlands to solar wall lights with a high luminous flux.

Related Blogs

Share Via:

Get in Touch with Us Now!

Got questions or feedback? We’d love to hear from you! Just fill out the form below, and our friendly team will respond ASAP.